Situation

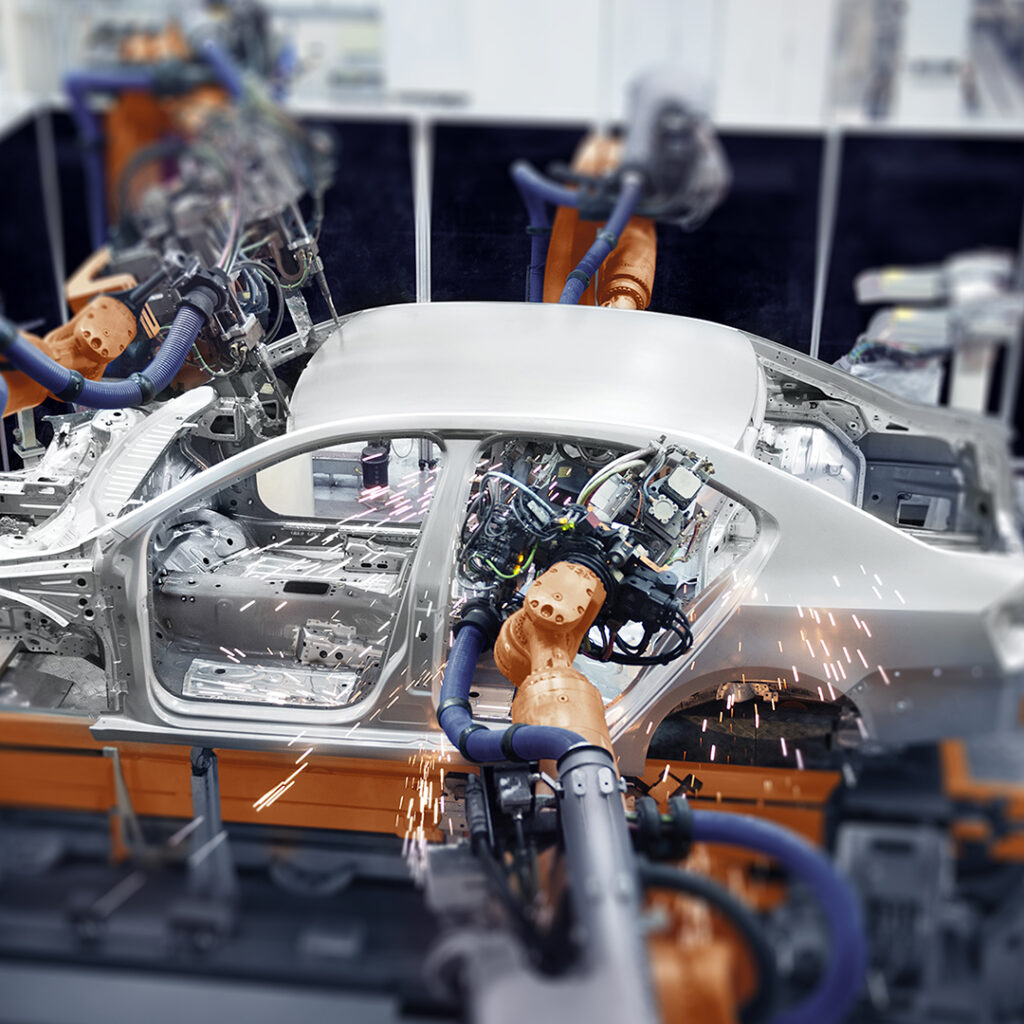

A global manufacturer of motion control systems was experiencing unpredictable downtime across its factory locations which was disrupting their end customers’ supply chain.

They wanted to improve OEE by digitizing the plant floor and installing smart sensors to automate monitoring of production systems to spot errors and determine when equipment needs maintenance.

These sensors and production systems need to be protected from outside threats, as any disruption to the manufacturing process costs hundreds of thousands of dollars per day and if exploited, valuable proprietary data can be lost or compromised

Solution

KeyScaler was deployed with the following benefits:

- Dynamic Device Key Generation (DDKG) technology established root of trust and enabled automated crypto-key generation at each authentication session.

- Zero touch device provisioning and registration with Microsft Azure IoT Hub

- Automated Device Identity Lifecycle Management for all production assets and monitoring of devices on the factory floor using x.509 certificates from their existing PKI provider

- KeyScaler Edge enabled the management of offline devices connecting via secure Edge gateways